| Sign In | Join Free | My entremaqueros.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My entremaqueros.com |

|

Brand Name : Sussman

Model Number : RF-SH

Certification : CE, SGS, ISO

Place of Origin : Wuxi, China

MOQ : 1 set

Price : negotiable

Payment Terms : LC, TT

Supply Ability : 10 sets/ months

Delivery Time : 60 days after deposit

Packaging Details : Film and steel

material thickness : 0.3-0.8mm

Forming speed : 8-12m/min

Roller stations : 18 stations

Roller material : GCr15, coated with chrome

main motor power : 7.5Kw

name : Double Deck Roll Forming Machine

Advantage of machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

1. Suitable Plate Material: thickness 0.3-0.8mm, Galvanized steel S235JR

2. Working Speed: 8-12meters / min

3. Forming machine: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Chain Driven 1.2 inches 20A double chain with longer shafts

7. Main Power with reducer: 7.5KW

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 5.5KW

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Panasonic, Japan English and Chinese Language

13. Touch Screen--Panasonic Japan

14. Encoder--Omron, Japan

15. Electric parts--Schneider

16. Outline of main about 4000mm*1350mmm*1200mm

17. Weight : about 12 tons

Main Components

|

Serial No. |

Commodity & Description |

Quantity |

|

1 | 5T manual uncoiler | 1 set |

|

2 | Leveing guiding | 1 set |

|

3 | Servo feeding device | 1 set |

|

4 | Main roll forming machine | 1 set |

|

5 | Hydraulic station | 1 set |

|

6 | Cutting device | 1 set |

|

7 | Finished products tabel | 1 set |

|

8 | PLC control system | 1set |

|

9 | Out tables | 1 set |

|

10 | Spare parts | 1 set |

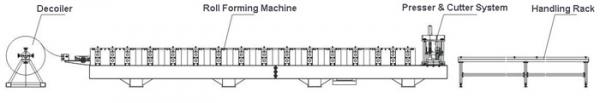

Working Flow of Roll Forming Machine

A.Passive Decoiler..........................................................To load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the heavy material.)

B.Servo Feeding Applicator............................................To feed the material accurately

C.Hydraulic/Press Punching...........................................To punch as requirements

D.Roll Forming Unit.........................................................To roll form as requirements

E.Hydraulic Cutting.........................................................To cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output Table................................................................Support the finished products

Uncoiling—Feeding&Leveling--Roll forming—Cutting—Products collecting

Profile of product

Pictures

|

|

Double Layer Roll Forming Machine , Galvanised Steel Roof Panel Making Machine Images |