| Sign In | Join Free | My entremaqueros.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My entremaqueros.com |

|

Brand Name : Sussman

Model Number : SS-CS

Certification : SGS.CE.ISO

Place of Origin : China

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, T/T

Supply Ability : 10 sets per month

Delivery Time : 45-60 days

Packaging Details : Film and steel

Name : Corrugated Roofing & Siding Roll Forming Machine

Material : 1.0-2mm Galvanized steel sheet

material thickness : 1.0-2mm

Forming stations : 18 stations

Roller material : 45# Steel with quenching 60mm shaft

Dirve system : 1.2 inc single Chain drive

power supply : 380V, 50Hz, 3Phase

Forming speed : up to15m/min

Machine weight : about 8 tons

Machine Dimension : 8mx1.6mx1.2m

Durable Corrugated Roof Panel Roll Forming Machine , metal wall panel roof Sheet Making Machine

Roll Forming Machine Technical Parameter

| Item NO |

Description |

Offered specification |

| 1.0 | Roll forming machine |

|

| 1.1 | Rolling speed | UP to 15m/min(not include cutting time) |

| 1.2 | Rolling thickness | 1.0mm-2.0mm |

| 1.3 | Raw material | Color painted coils |

| 1.6 | Dimension | About 8000×1600×1200(mm) |

| 1.7 | Effective width | 836mm |

| 1.8 | Feeding Coil width | 1000mm |

| 1.9 | Roller stations | About 18 stations

|

| 1.10 | Roller material | 45#forge steel, coated with chrome |

| 1.11 | Shaft diameter | Φ76mm |

| 1.12 | Transmission | By chain 1.2 inch |

| 1.13 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.14 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.15 | Tolerance | 10m+-1.5mm |

| 1.16 | Hydraulic station | 4kw |

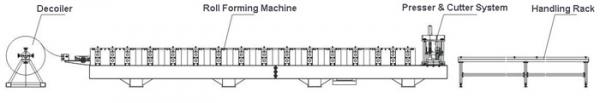

Main Components

| No | Name | Quantity |

| 1 | 5 ton passive de-coiler | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Control box | 1 unit |

| 4 | Hydraulic station | 1 unit |

| 5 | Out tables | 2 units |

Working Flow of Roll Forming Machine

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

Profile of product

Photo Gallery

Loading pictures

|

|

Durable Corrugated Roof Panel Roll Forming Machine , Metal Roof Roll Forming Machine Images |